0

Products Developed0

Projects Complete0

Feedback ReceivedJ N Metal

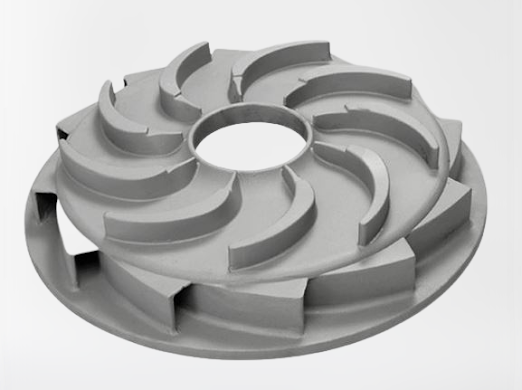

J N Metal A Leading Manufacturing And Supplier Of Ferrous & Non Ferrous Casting Since 1995. As Per Customer Requirements. By The Process Of Shell Moulding, Sand Casting, Investment Casting And Centrifugal Casting Process.

We Are An ISO 9001:2015 Certified Firm. Certification From TUV India Since 2015. We Have Our Own Foundry And Machining Shop Floor Facility With Highly Skilled Man Power.The Quality Control Is Done Through Imported Measuring Instruments.We Have Hardness Tester & All Require Measuring Devices.

Our Manufacturing Facility Located At Rajkot- Gujarat On India. Our Production Capacity Per Piece 0.030 Kg To 300Kg. Per Day Production Capacity 2000Kg To 5000Kg. We Strive To Deliver Product Of Supplier Quality Through Continuous Improvements And Manufacturing Excellence.

Our Mission

We shall strive to be leaders in this business by offering products of a world-class quality, and through constant technological innovation. We understand the needs of our customers and shall stay focused on them by offering them products, service and solutions of the highest quality.

Our Vision

Our vision is to be “Best in Class” in the market segments we serve.

Product Gallary

Quality Policy

J N Metal Are Committed To Achieve Customer Satisfaction By Supplying Quality Product To Meet Customer Requirement. Do Continuosly Improvement At All Level In Process, Infrastructure & In System.

Stringent Standard For Acceptance Of Raw Materials Lead To Perfect Quality Circle, Emphasizing Not Only Flawless Products But Improvement Through Various Innovative Moves.Quality Function ,Analysis And Statics Are Performed As Per The Product Needs And Can Be Compared To International System/Standards.

J N Metal Is Fully Equipped With In House Lab With Every Required Chemicals And Instruments For Analysis Of Different Non-Ferrous Alloys The Compnay Provide Guaranteed Chemical Analysis Of Non-Ferrous Metals As Per IS, BS & ASTM.

The Company Is Fully Equipped With Inspection Room With Highly Precised Testing Instruments Like Digital Varnier, Go-Nogo Gauge, Bore Gauge, Dial Gauge, Veinier Etc.

In the casting process, first few castings will be inspected dimensionally and the pattern is qualified afterward, only a few random inspection will be done. Every casting must be inspected for finding out the defects in the casting process.

- Visual Inspection

- Hydrostatic Pressure Test

- Magnetic Particle Inspection

- Radiographic Examination

- Ultrasonic inspection

- Dye Penetrant Inspection

- Spectro Testing

- Micro Examination

- Tensile Test and Etc.

Value Added Service

JNM has industrialized a wide array of value added services to meet our customer's specific and ever changing requirements. J N Metal is known for its prompt reply.

We operate with a human capital of 50 people and are accredited with ISO 9001:2015.

Certificate

.jpg)

.jpg)